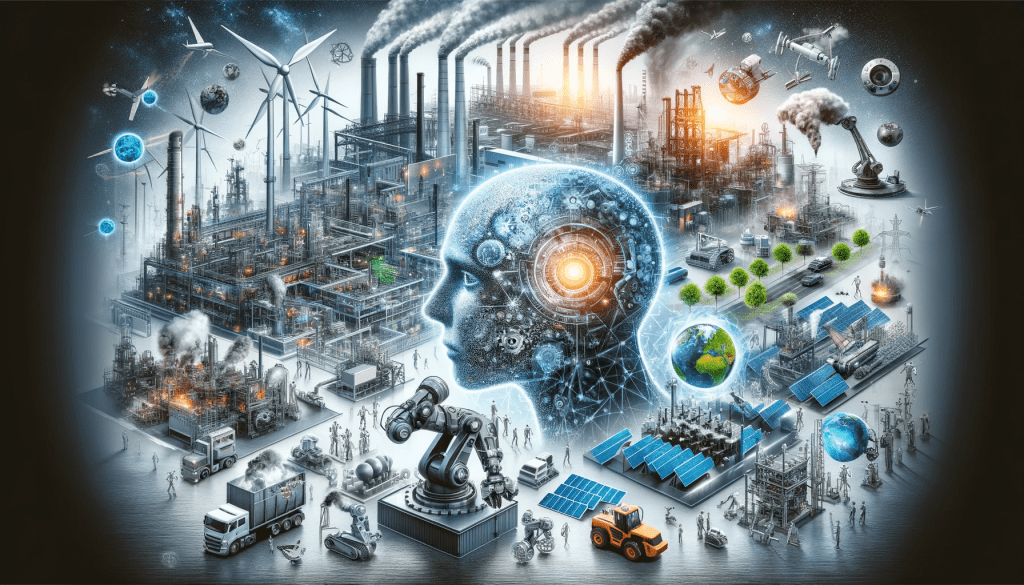

As we approach the end of the year, it’s pivotal to reflect on the significant strides and challenges within the heavy industry sector. This sector, known for its immense contribution to the global economy, has experienced a year of dynamic change and adaptation, characterized by technological advancements, environmental concerns, and market shifts.

This article will delve into the key developments and trends that have shaped the heavy industry landscape in the past year.

Technological Innovations and Automation

The heavy industry sector has witnessed significant technological advancements, particularly in the realms of artificial intelligence (AI) and machine learning. These technologies have been pivotal in transforming factory operations, enabling predictive maintenance that reduces downtime and extends equipment life. Moreover, machine learning algorithms have revolutionized quality control processes, ensuring unprecedented precision.

The rise of robotics and automation has been equally transformative. Collaborative robots, or cobots, are now commonplace, working alongside human operators to enhance productivity. Additionally, the use of automated guided vehicles (AGVs) and drones for material handling and inventory management has streamlined logistics within manufacturing units.

Environmental Sustainability

Sustainability has emerged as a key focus area. The shift towards renewable energy is evident, with heavy industries increasingly investing in solar and wind energy projects. Carbon capture and storage (CCS) technologies are also being developed to mitigate environmental impact.

Moreover, there’s a growing trend towards using recycled materials in manufacturing, along with implementing water conservation methods and energy-efficient machinery, underscoring a commitment to sustainable manufacturing practices.

Market Dynamics and Economic Impact

The past year has also been marked by significant challenges in global supply chains, prompting industries to adapt through nearshoring and diversifying suppliers. The digitalization of supply chain management has gained momentum, offering enhanced resilience and visibility. Economic fluctuations, especially in raw material costs, have impacted production and pricing strategies. Despite these challenges, there’s been a strategic focus on research and development to innovate and tap into emerging markets.

Future Outlook

Looking ahead, the integration of Internet of Things (IoT) and 5G technology is expected to play a crucial role in the industry, enabling real-time data analysis and improved connectivity. The concept of smart factories, with fully integrated and automated systems, is likely to become the norm, further boosting productivity. Additionally, the industry is poised to witness increased regulatory and public pressure towards sustainability, driving innovations in eco-friendly technologies and sustainable resource management.

Personal Reflections: Navigating the Future of Heavy Industry

Embracing Change and Innovation

As a professional deeply engaged in the analysis and discussion of various industries, I find the transformations in the heavy industry sector particularly striking. The rapid integration of advanced technologies like AI, machine learning, and robotics isn’t just a testament to human ingenuity but also a necessary adaptation to the ever-evolving market demands and environmental concerns. These innovations are reshaping the very fabric of traditional industrial practices, paving the way for a more efficient, sustainable, and economically viable future.

The Sustainability Imperative

The shift towards environmental sustainability in heavy industry is not only commendable but essential. As we grapple with the pressing issues of climate change and resource depletion, the industry’s move towards renewable energy sources and sustainable manufacturing practices is a critical step in the right direction. This evolution reflects a growing recognition that economic growth and environmental stewardship must go hand in hand.

Responding to Market Dynamics

The challenges posed by global supply chain disruptions have highlighted the need for resilience and flexibility in the heavy industry sector. The industry’s response, through diversification of supply chains and adoption of digital solutions, is a robust example of adaptability in the face of adversity. It underscores the importance of being prepared for unexpected market shifts and the value of strategic planning.

Looking Ahead with Optimism

The future outlook for heavy industry, with its focus on smart factories and fully integrated manufacturing processes, is immensely promising. It suggests a scenario where efficiency and innovation continue to drive the sector forward. However, this optimistic view must be tempered with a realistic understanding of the challenges ahead, including regulatory changes, technological disruptions, and the ongoing need for skilled workforce development.

Conclusion

The heavy industry sector, over the past year, has not only shown resilience but also a remarkable capacity for innovation and adaptation. The strides made in technology and sustainability, coupled with the ability to navigate economic and market challenges, highlight the sector’s crucial role in the global economy. As we look forward, the sector is well-positioned for continued growth and transformation, underpinned by technological advancements and a commitment to environmental responsibility.

Leave a comment